When I first heard about 3-D printing, one of my first thoughts was that it could be used to make repair parts for any equipment that has small, specialized plastic pieces (usually injection molded) that are difficult to produce, stock, inventory, catalog, and sell. In the glorious future I foresaw, appliances would come with .stl files for all their little proprietary plastic parts. It would enhance repairability while unburdening the supply chain from having to manage all the little pieces that are then saddled with high logistical costs.

When I first heard about 3-D printing, one of my first thoughts was that it could be used to make repair parts for any equipment that has small, specialized plastic pieces (usually injection molded) that are difficult to produce, stock, inventory, catalog, and sell. In the glorious future I foresaw, appliances would come with .stl files for all their little proprietary plastic parts. It would enhance repairability while unburdening the supply chain from having to manage all the little pieces that are then saddled with high logistical costs.

We’re not there yet. Manufacturers still guard their proprietary design specifications with a paranoia that rivals the way commercial software developers guard their source code. A sea of evidence (in the latter case, the existence of the free and open source software movement) suggests that we’re all better off when people who make our tools don’t keep secrets, but no doubt it will be a long time before intellectual property worshipers understand.

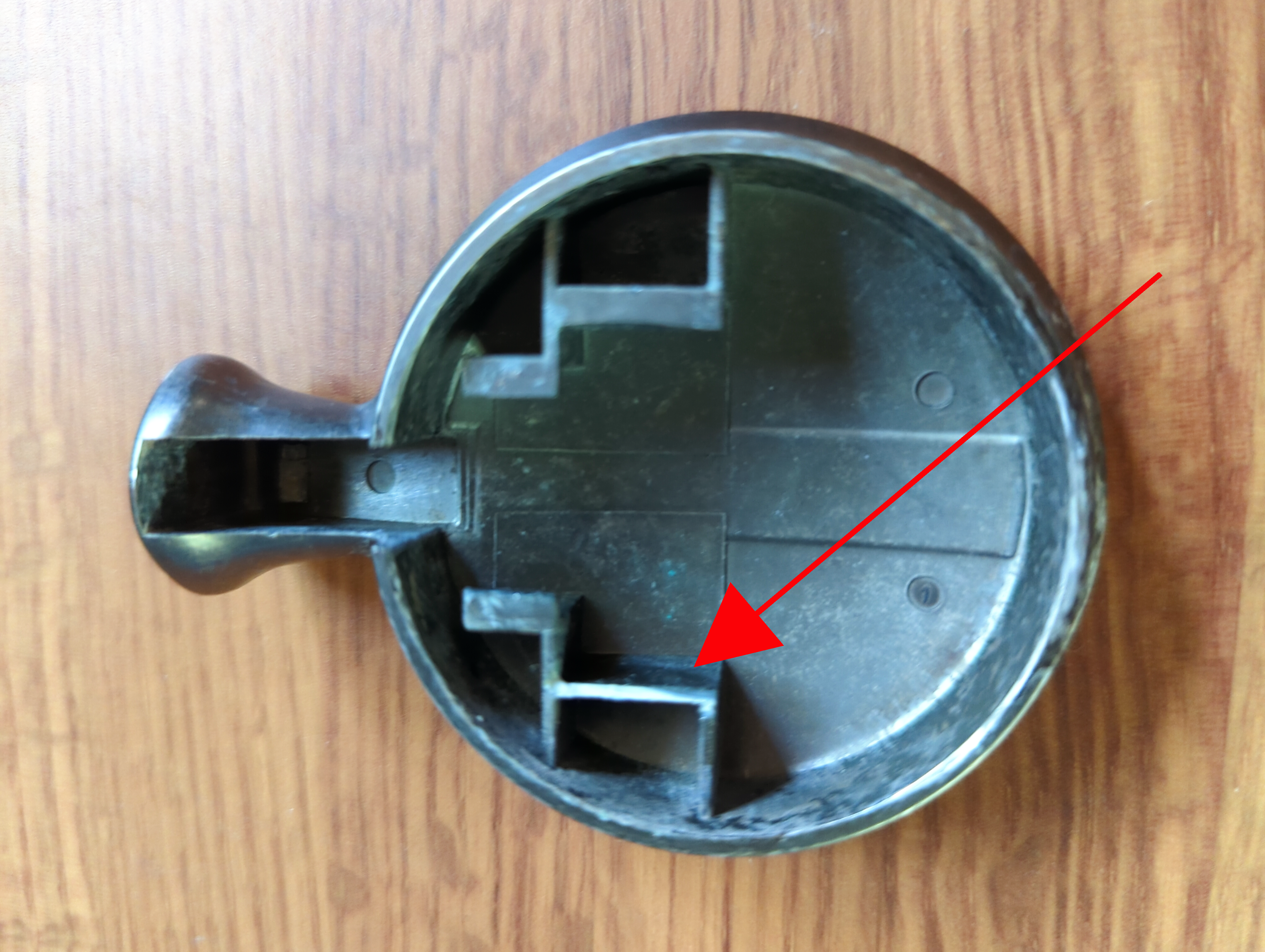

So I was frustrated when one of the temperature control levers on one of my Delta Series 17 faucets kept falling off. I took a deeper look at the 20-year old plastic bit, and found that a tiny tab had broken off inside it.

So I was frustrated when one of the temperature control levers on one of my Delta Series 17 faucets kept falling off. I took a deeper look at the 20-year old plastic bit, and found that a tiny tab had broken off inside it.

The broken bit was long gone (probably before I bought the house), and even if I had it the likelihood that it could be successfully glued back on was small. The entire part would have to be replaced.

Worse, even. That part doesn’t seem to be available from anyone, anywhere. The only repair option (short of replacing the entire valve and re-tiling the shower!) was to buy the closest version of the Series 17 faucet still in production, throw away the $175 fixture, and put the lever (a part whose production cost is certainly less that one dollar) on my old faucet, where it would not match as the style and finish I have is no longer available. Sad, and crazy.

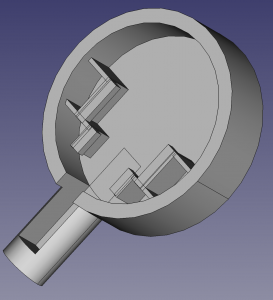

But this is what I dreamed that 3-D printers could do! I broke out my trusty calipers, fired up FreeCAD, and a couple of hours later I had a design.

One of the nice things about using 3-D printers is that you can design iteratively. As a writer and software designer, the approach appeals to me: to a quick proof-of-concept, learn about the nuances you didn’t appreciate at first, then make refinements until you get what you need. I realized, though, that the tolerances on this part were going to be tight, so as much as I could I duplicated the functional parts exactly as they were in the original and I used tight tolerances.

I printed it in blue PLA because that’s what I had available. It was just a prototype, after all. Lo-and-behold, the part printed perfectly the first time and it fit exactly! I was now regretting having used blue material, though it didn’t look nearly as bad as I’d feared. The photo really enhances the blue; it’s not quite as jarring in real life. Still, blue.

I printed it in blue PLA because that’s what I had available. It was just a prototype, after all. Lo-and-behold, the part printed perfectly the first time and it fit exactly! I was now regretting having used blue material, though it didn’t look nearly as bad as I’d feared. The photo really enhances the blue; it’s not quite as jarring in real life. Still, blue.

I’d seen some social media posts of people who finished their 3-D prints with a waxy substance called Rub ‘n Buff, so I bought a tube, did some sanding, et voilà!

Far from a perfect match (I could probably find a better shade of Rub ‘n Buff than “Spanish copper”) but I’m perfectly happy with it.